如何制作微芯片

了解芯片制造过程中的步骤以及在洁净室里工作的感觉

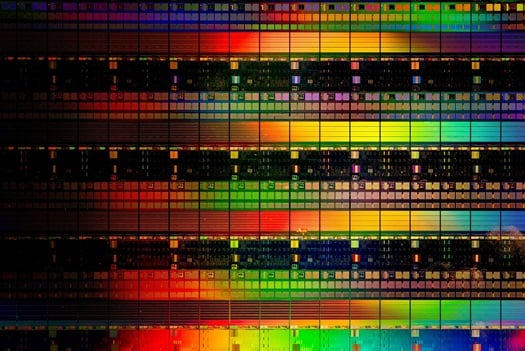

微芯片是通过在硅晶片上建立相互联系的图案层制成的。

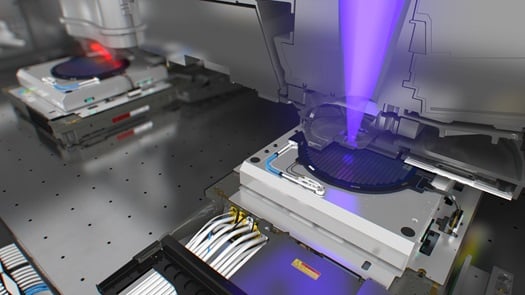

微芯片制造过程涉及数百个步骤,从设计到大规模生产最多需要四个月的时间。在机器人将其珍贵的晶圆从机器上运输到机器时,在芯片制造商的晶圆厂(制造设施)的洁净室(制造设施)中,保持了严格的控制。

微小的摩天大楼

现代芯片最多可以具有100层,所有这些层都需要以纳米精度(称为“覆盖”)彼此对齐。芯片上打印的功能的大小取决于图层,这意味着不同类型的光刻系统用于不同的层。我们的最新一代EUV(极端紫外线)机器用于具有最小功能的最关键层,我们的DUV(深紫外)机器对于具有较大功能的不太关键层。

“干净”有多干净?

如果即使是最小的灰尘或其他外来材料最终都会放在晶圆上,它可能会破坏微芯片,因此芯片制造商要小心地保持其晶圆厂清洁。到底有多干净?比外部空气清洁约10,000倍。大多数芯片制造商的“ ISO 1级”洁净室是“零灰尘”,这意味着每立方米的空气尺寸不超过100至200 nm之间的10个颗粒,而无需大于200 nm。相比之下,一家干净的现代医院每立方米有大约10,000个灰尘颗粒。

洁净室内的空气被过滤并连续再循环,员工穿着特殊的衣服(有时称为“兔子西装”),以帮助保持空气颗粒的自由。

ASML机器也在我们的EUV和DUV工厂内的洁净室中制造Veldhoven,荷兰。

了解有关在芯片制造商工厂工作的更多信息客户支持工程师。

机器中的机器

包括光刻机器

平均晶圆每月开始

建造工厂的成本

芯片制造过程的步骤

芯片制造商的类型

集成设备制造商(IDM),例如英特尔和三星设计和制造芯片。另一方面,铸造厂是针对其他公司制造筹码的公司。TSMC,GlobalFoundries和UMC是这种类型的芯片制造商的例子。第三种类型的芯片制造商是“ Fabless半导体公司”,例如高通公司,NVIDIA和AMD,他们仅通过专注于芯片万博苹果手机客户端设计来避免建造和维护生产设施的高昂成本。这些公司可能会将其生产供应到铸造厂。

阅读有关微芯片的更多信息

半导体制造的关键步骤

现在您了解了基础知识,是时候进行更深入的潜水了。准备了解制作微芯片的六个最关键的步骤吗?