光线和激光器

从可见的蓝光到看不见的极端紫外线,ASML的光刻机器将创新保持在光线和激光下向前移动

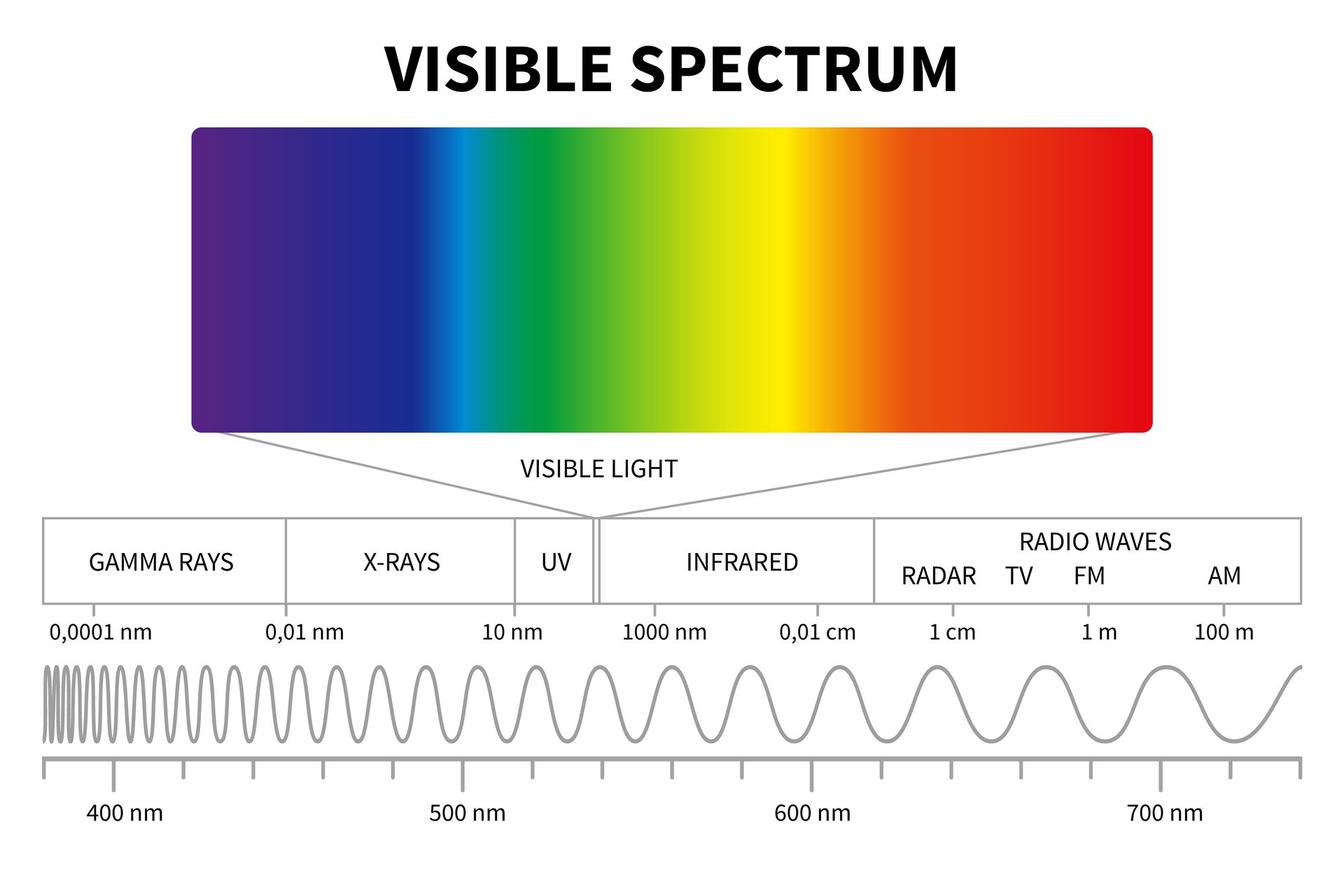

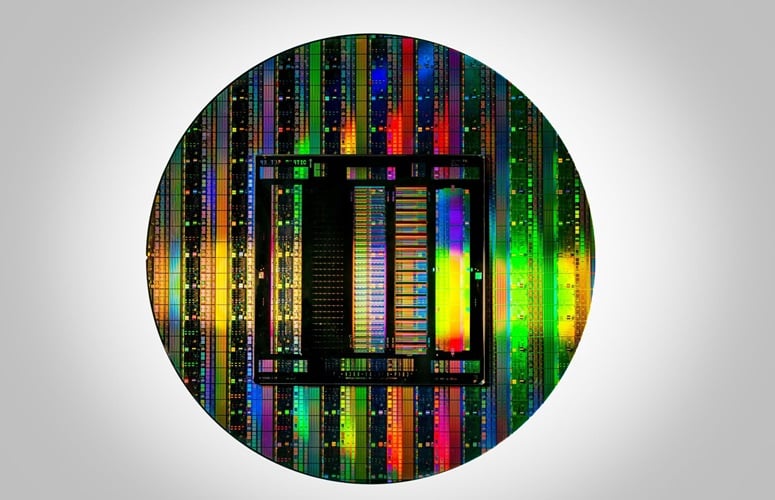

什么是光波长?像海中的波浪一样,光线作为一系列峰和槽旅行。峰之间的距离称为波长。光的波长越短,可以在光刻过程中打印的微芯片特征越小。

在整个ASML的历史中,我们都支持芯片制造商过渡到新的光刻波长,从而使更先进的微芯片成为可能。从可见的蓝光到ASML的独家紫外线(EUV)技术,每一步都需要创新光的产生方式。万博manbetx官网登录

汞灯:从蓝色到紫外线

建立ASML时,光刻的最新光源是汞蒸气灯。通过将电力传递到包含汞的灯泡中,这会产生光。电流会加热汞,直到它变成一个排放各种波长的血浆。使用干扰过滤器选择所需的波长。

我们的第一个光刻系统使用此设置来创建具有436纳米(NM)波长的蓝光,称为Mercury G-Line。它们可以打印出小至1微米(1,000 nm)的功能。为了启用较小的功能,我们很快切换到无形的紫外线(UV)光,波长为365 nm。这些后来的I线系统将特征大小推向1微米以下,最终达到220 nm。

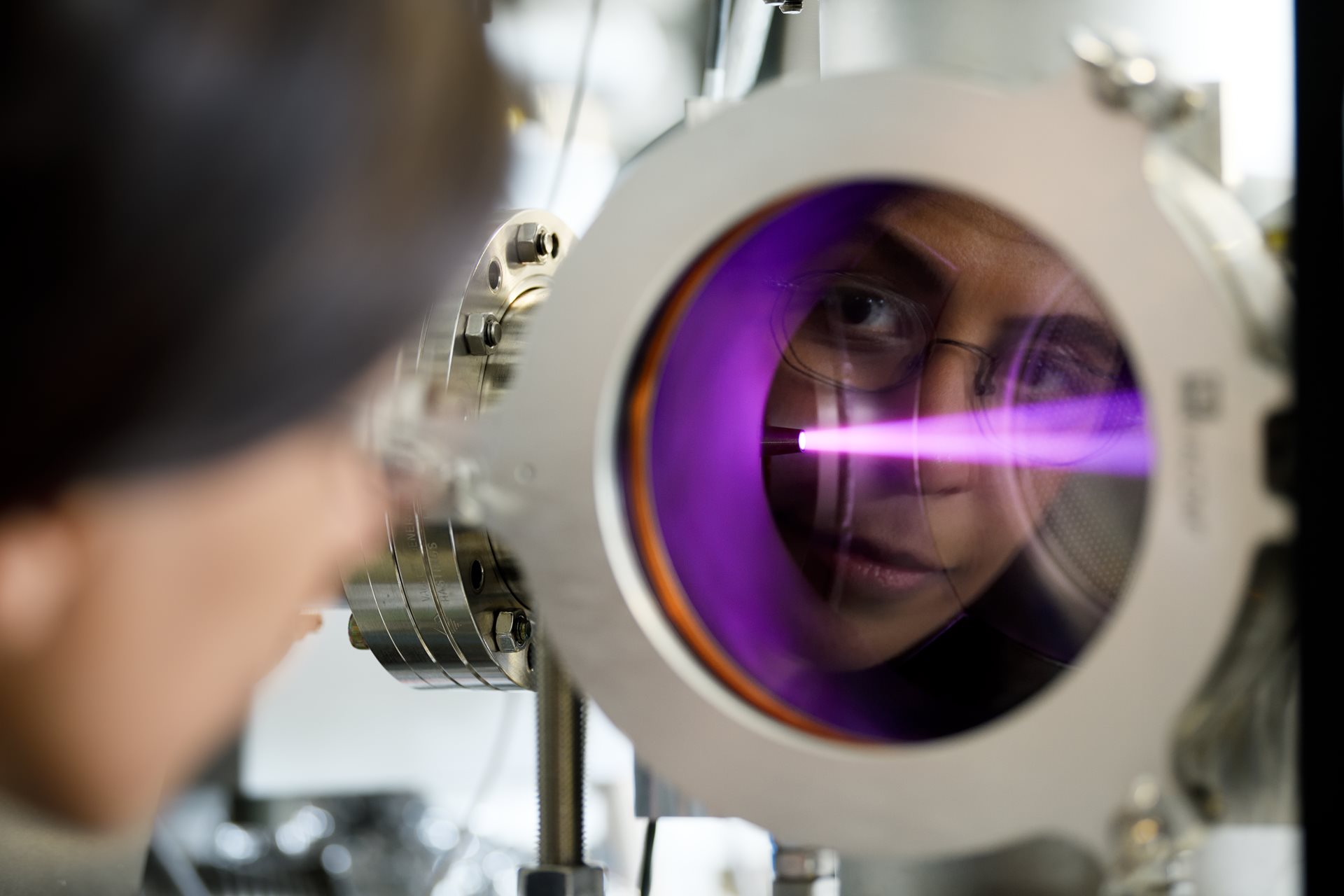

激光和杜夫

在1980年代中期,该行业对较小功能的需求导致了较短的波长转变。这次,需要一种全新的光线:激光。特别是深紫外(DUV)准分子激光器。这些激光器使用通常不混合的气体混合物。但是,当施加足够的能量时,两种气体的原子会结合在一起,形成激发的临时分子(准分子)。激发分子释放出多余的能量,因为光的波长取决于所使用的气体。

KRF:杜夫黎明

第一个DUV系统基于两个元素的组合使用了准分子激光器:K和氟。这些K-fluoride(KRF)激光器产生的光,波长为248纳米(NM)。150 nm KRF系统缩减了从280 nm的尺寸,这是先前的ILINE系统。现代KRF系统现在可以生产到80 nm的功能。

与ARF更深入

进入紫外线光谱,下一代DUV光刻系统使用氩气(ARF)精液激光器,可产生以193 nm为单位的光线。这使得打印的尺寸为38 nm。

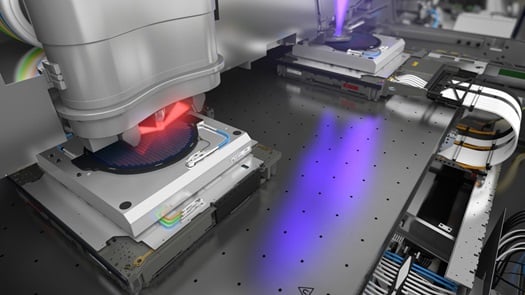

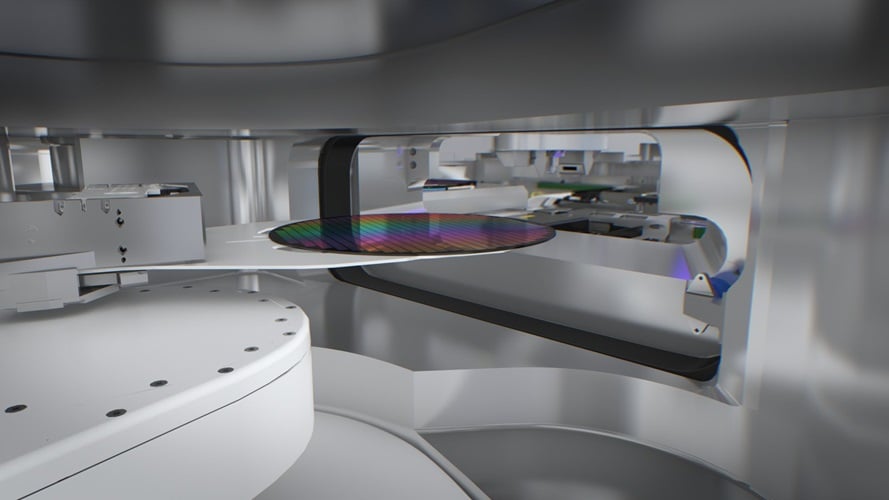

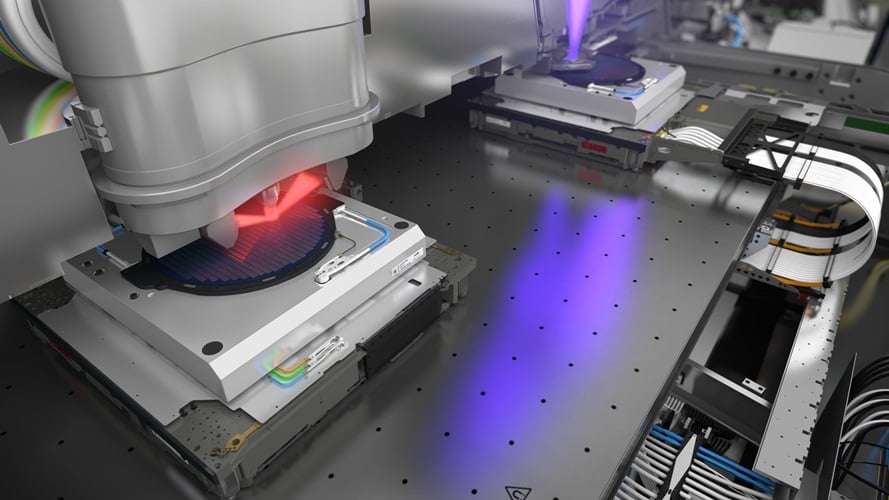

创建EUV光

EUV光刻这是一种万博manbetx官网登录完全独有的ASML技术,它使用的光线为13.5纳米的波长。该波长比Duv Light短14倍。

EUV光自然发生在外层空间。但是,为了使EUV光刻成为可能,我们需要设计一种在系统中创建此类光线的方法。因此,我们开发了一种彻底的新方法来生成光刻的光。

在我们的激光产生的血浆(LPP)源中,直径约25微米的熔融锡液滴以每秒70米的速度从发电机中弹出。当它们掉落时,液滴首先被低强度的激光脉冲击中,从而使它们变成煎饼形。然后,更强大的激光脉冲使扁平的液滴蒸发,以产生发出EUV光的等离子体。为了产生足够的光以制造微芯片,此过程每秒重复50,000次。

;

;

;

;

;

;

;

;

;

;