测量准确性

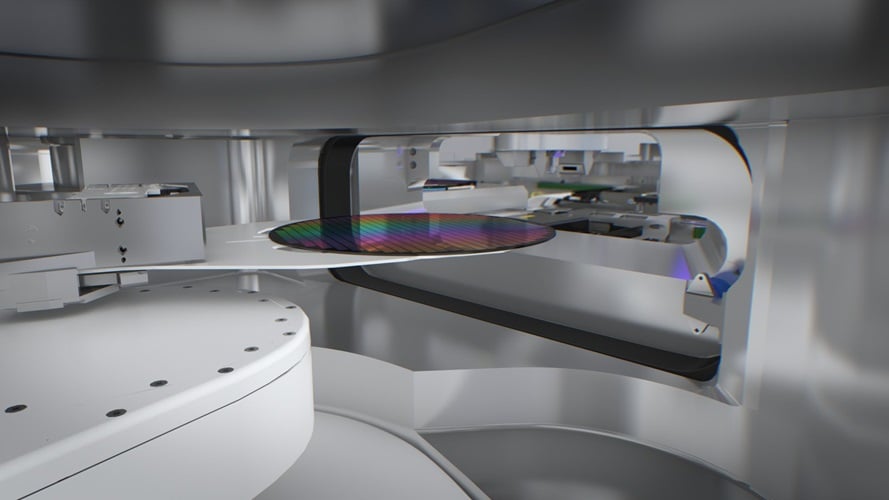

严格评估光刻过程的每个元素的准确性。因为即使是最小的错误也可能导致缺陷芯片

更多关于...

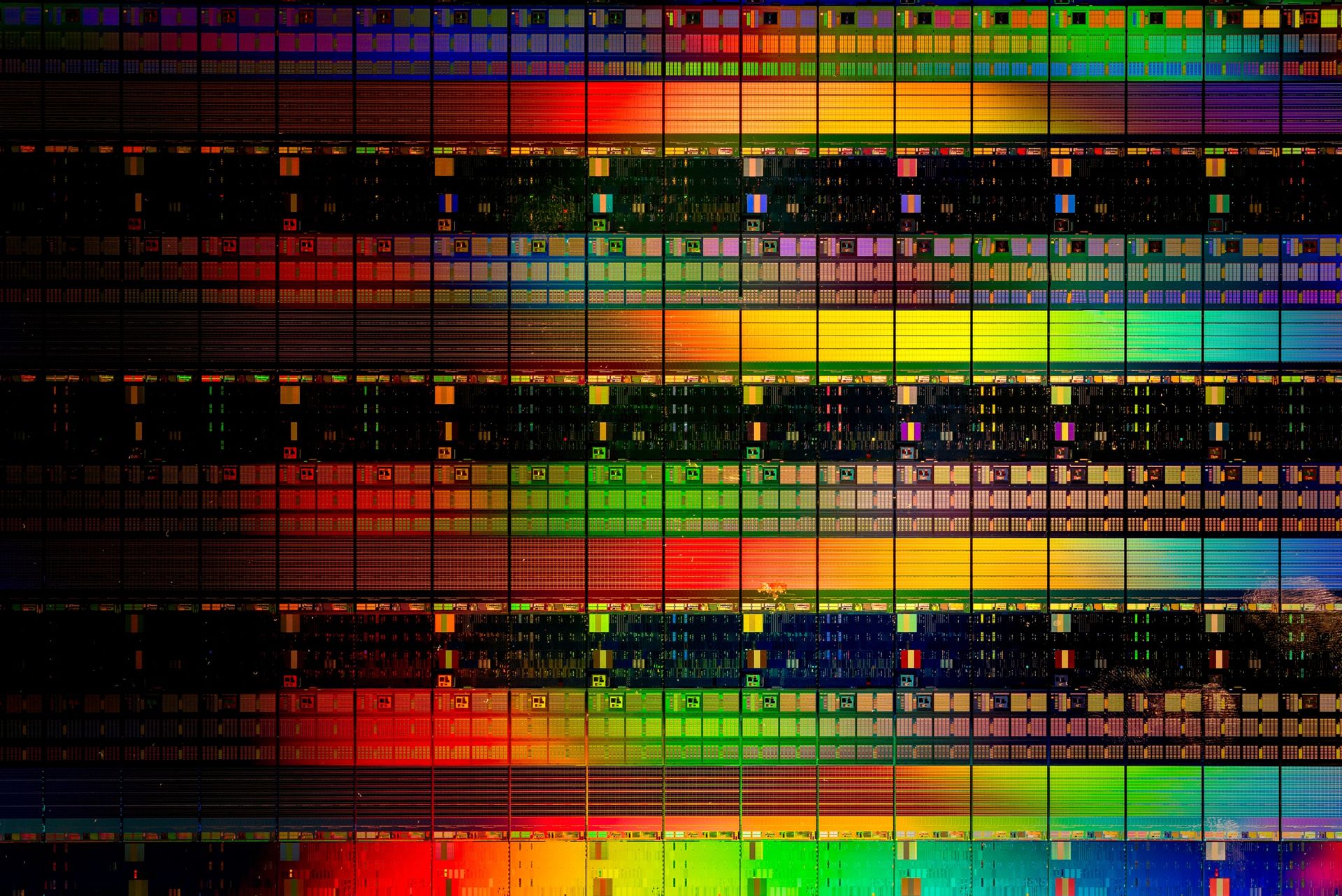

芯片制造商使用我们的产品打印芯片图案,并使用高级计量系统和软件检查这些图案,从而使其提高准确性和产量。

计量和检查的类型

有两种方法可以检查芯片上印刷特征的质量:基于衍射的光学测量和电子束检查。

衍射检查了光线如何从晶片中反射,而电子束与晶片接触时的电子束会散射。

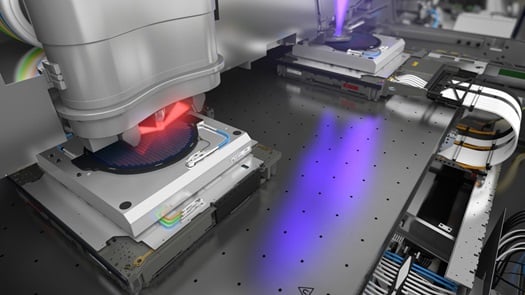

ASML使用两者:我们的Fardstar系统使用基于衍射的测量来评估晶片上的模式质量,而HMI电子束检查系统有助于定位和分析单个芯片缺陷。

结合来自我们内部光刻计算机的基于传感器的信息以及一组复杂的软件算法,Faredstar和HMI系统提供了大量数据,用于优化其制造过程的大量数据。

光学计量学

fardstar

ASML的FARDSTAR系统做出了他们的名字所暗示的:它们可以帮助我们的客户提高其产量,或者晶圆上的功能芯片比例。Fardstar允许制造商跟踪关键生产参数,例如覆盖(将两层芯片对齐的精度)。我们的Fardstar系统通常集成到生产线中,以便它们可以快速,准确地测量,从而将数据循环回光刻系统,以实时校正制造过程。

这个怎么运作

衍射

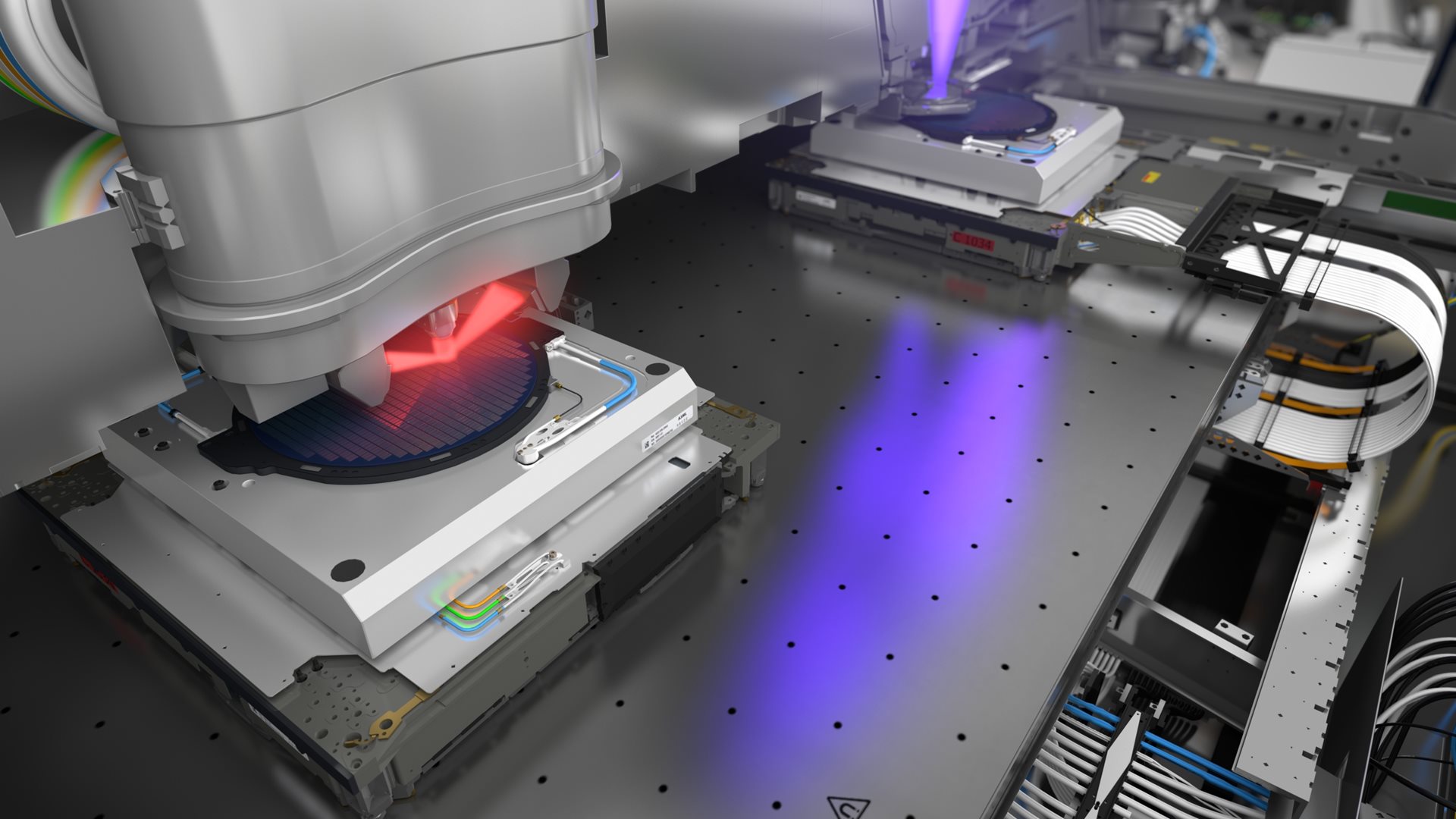

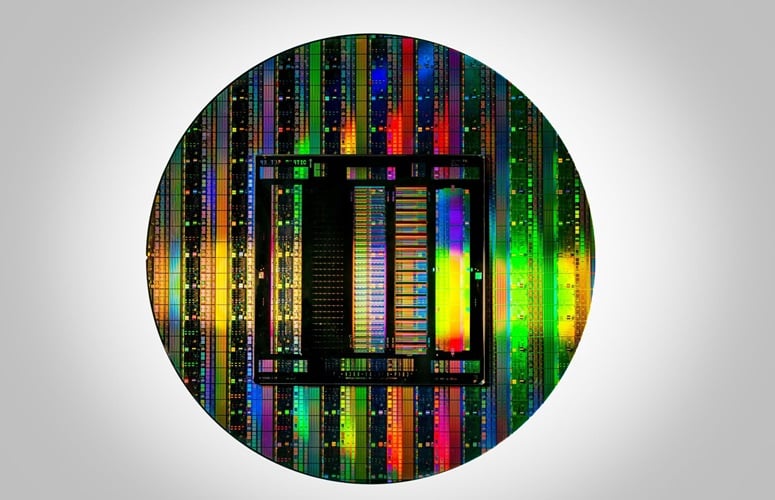

Fardstar是一个基于衍射的光学计量系统,它应用了一个简单的事实,即对象的形状决定了光的反映方式。例如,将一束光束照在晶圆上的重复线条上,您可以轻松预测所产生的散射光的模式应该是什么样子。如果您使用高分辨率数码相机收集散射的光,则可以快速确定预测与现实的匹配程度,从而打印了线的模式。

快速,准确的晶圆计量学

In wafer metrology, key manufacturing parameters such as overlay (the accuracy with which two layers of a chip are aligned) and focus (how sharp the image is) are monitored by measuring how well a particular repeating pattern (the ‘metrology target’) is printed on the wafer. These measurements are made at marked locations across the wafer.

集成到生产线

在屈服之星之前,将晶片从生产线中取出,以手动测量。通过将我们的解决方案集成到生产线(或“轨道”)中,芯片制造商现在可以使用fardstar快速,准确地收集其计量数据,从而更好地控制其生产过程。使用控制软件对计量数据进行分析,并实时回到光刻系统,使客户能够进一步调整制造过程以获得最佳收益。

从重复模式到真实结构

我们基于衍射的计量的最新发展具有新的光学技术,可生成更准确的数据,更快,每批晶片的数据点数千个数据点。Fardstar与我们的光刻系统的生产率匹配,以控制最先进的芯片节点。此外,与竞争对手的扫描电子显微镜(SEM)溶液相比,FardStar用于毕业后的计量,以更准确和更高的测量速度检查实际设备结构。

电子束计量和检查

HMI电子束解决方案

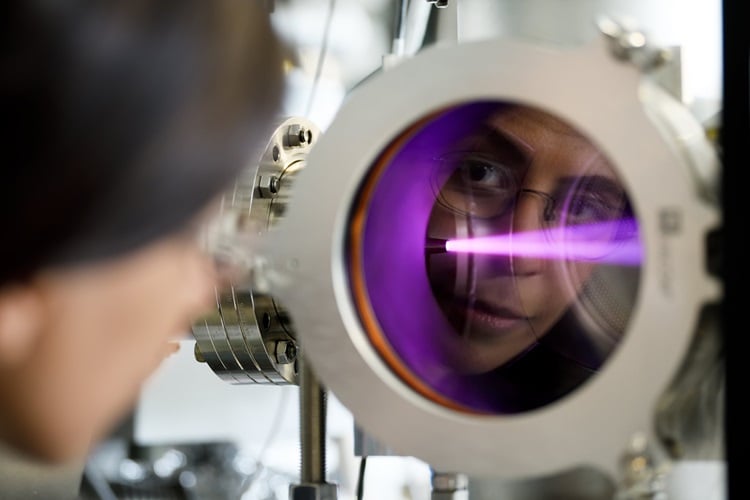

对于当今的高级微芯片,像几种纳米一样小的缺陷可以使整个芯片变得无用。通过其1纳米分辨率,电子束检查提供了正确的眼睛,可以发现那些微不足道的错误。

ASML位于电子束计量和检查方面的发展。电子束比fardstar获得更高的分辨率,但是它的测量更慢,这意味着通常在图案蚀刻到晶片上后使用。

这个怎么运作

“ e”用于“电子”

电子束技术已经万博manbetx官网登录存在了数十年。基本概念是将金属线加热到释放电子,并通过电场和磁场加速并形成光束。与可见的和紫外线(但就像极端紫外线一样)不同,电子束必须在真空中传播,因此在达到目标之前不会偏转或吸收它们。

在半导体行业的计量学和检查中,电子梁扫描了整个晶圆。电子撞击表面并将一小段距离穿透到材料中,在散射之前产生新的“次级电子”。与基于衍射的测量值一样,测量辅助电子的散射使我们能够建立表面非常高分辨率的图像。光束越聚焦,可以测量的细节越小。

加速电子束成像

电子束测量值的棘手之处在于它们非常慢。结果,它们通常仅在芯片制造的早期研发阶段使用,而时间却不再是问题。

ASML正在引领加速电子梁测量值,以便制造商可以在数量生产中享受好处。我们这样做的一种方法是开发将电子束测量重点放在缺陷更可能或更关键的特定热点上的解决方案。

多束检查

我们最近的电子梁系统,HMI Escan 1000,将高分辨率电子束测量与最先进的计算建模,机器学习算法和来自光刻系统的数据相结合。

HMI ESCAN 1000使用多个电子束来更快地检查晶圆的更大表面积。Escan 1000于2020年5月首次运送给客户,是一个3x3多光束系统,可以将吞吐量增加约9倍。但是我们不打算在此停止 - 我们计划增加子孙后代的光束和光束分辨率的数量,以与芯片制造商的产品路线图要求保持一致。

在线晶圆和标线检查

通过加速过程并将搜索范围缩小到特定区域,可以直接在生产线中使用电子束进行晶片检查,同时保持生产率水平。

扫描仪计量学

精确和速度对于当今的高级芯片制造机来说至关重要。但是,由于物质缺陷,温度波动和大气压力变化,亚纳米的不准确性不可避免地逐渐蔓延。扫描仪计量软件使用机器中的MangieProcesses的计算模型来预测和协调我们光刻系统中功能强大的机电模块如何表现以补偿物理缺陷并最大程度地提高系统性能。

阅读更多

统计所有

光刻系统(扫描仪)必须以亚纳米精度为24/7,同时以令人难以置信的速度加速机电雄性模块。例如,标线阶段在接近16克,晶圆阶段加速至7G。这比喷气式战斗机更加加速。

不可能机械地构建能够保持这种对齐和精确度的机器,以这些速度加速,并且在没有扫描仪计量学的帮助下进行当今计算机芯片所需的可靠性和可重复性水平。

芯片调整

光刻系统是芯片制造过程中最“可调节的”工具。系统中有许多“旋钮”,可用于对每个晶圆上的每个单独的芯片进行特定的小调整。

通过不断测量光刻系统的行为,使用扫描仪计量学计算,然后协调物理组件(“旋钮”)需要进行的许多微小调整,以优化每个微芯片上的模式。

数百个传感器,包括位置,温度,能量和运动传感器,测量系统内的每个方面。先进的算法用于解释这些大量数据,并使用数千个执行器以非常小但详细的方式协调必要的调整,但在亚纳米尺度上进行了详细的调整。

启用3D芯片架构

扫描仪计量学在确保某种类型的记忆芯片(称为3D NAND)的质量中起着特别关键的作用。这些是SD卡中使用的闪存芯片,固态硬盘驱动器和智能手机。以前以2D制作,引入3D技术是改变游戏芯片的游戏规则。万博manbetx官网登录

将存储单元互相堆叠大大增加了存储,并使芯片能够更有效地运行并使用更少的能量。但是这些芯片是复杂的,要衡量的挑战。3D NAND芯片制造商必须制造在2D芯片上发现的复杂结构,然后将它们对准垂直平面,并使用微小的垂直通道将它们连接起来。

许多计量系统无法穿透这些3D结构以观察芯片以检测制造问题,因此生产在很大程度上依赖于扫描仪计量软件来优化质量。通过分析在光刻系统中添加图层时生成的大量数据,该软件可以反馈以优化对齐和覆盖。

模式保真度

模式保真控制(PFC)是芯片制造中的新范式,旨在提供我们整体光刻方法的全部好处。通过在整个芯片开发和制造过程中绘制和分析来自更广泛来源的最精确数据,它为芯片制造商提供了前所未有的见解,以了解他们实际上在晶圆上打印的模式。然后,强大的算法将这些见解转化为动作。这些动作是在光刻系统中实施的,以防止模式缺陷并使高产,即使生产最复杂的芯片也是如此。

阅读更多

传递数据

单个光刻系统每周就可以从其传感器中产生31吨数据 - 这是一年来Hubble Space望远镜收集的三倍。

PFC的愿景是从微芯片开发和生产过程中尽可能地汲取相关数据。为此,我们与工厂中的其他半导体设备制造商合作,为芯片制造商带来最大的好处。

我们收集并使用来自系统中的系统中的数据,包括FARDSTAR计量系统,电子束检查工具和我们的光刻系统中的晶圆映射。我们还利用我们的信息计算光刻解决方案,以及生产线上的任何非ASML设备。最后,我们正在开发一系列模式的保真度计量选项,这些选项可以通过可以集成到生产线的方式来利用电子束测量的高分辨率。

数据分析

首先,与我们收集的大量数据(如覆盖性能或照明配置)在诸如覆盖性能或照明配置之类的领域专家合作,首先是手动处理的,以删除任何虚假关系(域专家看到相关性,但知道没有因果关系)。然后,使用高级计算机模型和机器学习算法分析该数据,以发现导致缺陷的许多因素之间的相互作用,从而影响成品微芯片的性能。最后,我们计算合适的校正,然后将其应用于光刻系统。这将提供制造商对低于10 nm功能的高级控制。

;

;

;

;

;

;

;

;

;

;